The main differences between national standard aluminum materials 6063-T6 and 6063-T5 lie in chemical composition, heat treatment status, mechanical properties and applicable scenarios.

1. Comparison of chemical composition:

| Materials | 6063-T5 | 6063-T6 |

| 硅(Si) | 0.20-0.6% | 0.2-0.6% |

| 铁(Fe) | ≤0.35% | ≤0.35% |

| 铜(Cu) | ≤0.10% | ≤0.10% |

| 锰(Mn) | ≤0.10% | ≤0.10% |

| 镁(Mg) | 0.45-0.9% | 0.35-0.6% |

| 铬(Cr) | ≤0.10% | ≤0.10% |

| 锌(Zn) | ≤0.10% | ≤0.10% |

| 钛(Ti) | ≤0.10% | ≤0.10% |

| 铝(Al) | Rest | Rest |

2.Comparison of heat treatment states:

cc6063-T5: After air cooling and aging treatment, the deformation coefficient is small.

• 6063-T6: After water cooling and aging treatment, the deformation coefficient is large and the hardness is high.

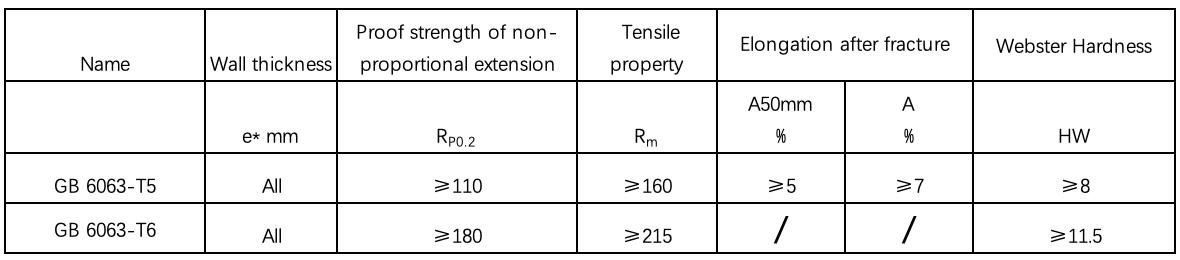

3. Comparison of mechanical properties:

4. Comparison of applicable scenarios:

• 6063-T5: Applicable to places with low strength requirements, such as decoration, doors and windows.

• 6063-T6: Applicable to industries with higher strength, such as glass curtain walls, external structures of high-rise buildings, automobile manufacturing and aerospace12.

5. Price difference:

Generally speaking, the price of 6063-T6 is higher than that of 6063-T5 because it has higher strength and hardness and is suitable for scenarios with higher requirements.